Pipes and piping systems are the backbone of our modern society, and there are few places where this becomes more apparent than in the oil and gas industry. Besides the thousands of miles of pipelines worldwide that bring the crude oil, natural gas, or other products from one place to the other, pipes are also crucial components of oil rigs, the tankers, the refineries, and a wide variety of other installations. Because just like a body cannot function without veins and arteries, industrial installations cannot function without a multitude of piping systems.

Since it is impractical, time-consuming, expensive and dangerous to weld every single pipe joint on site, large segments of the pipe systems are usually pre-fabricated in pipe-shops, often including sophisticated CNC machines for a number of special tasks. These pipeshops allow for fabrication of large quantities of segments, or spools, which can be prepared cheaper and more easily inside the shop, and can then be installed on-site faster and with less hot work.

However, in order for a pipe-shop to be as efficient as possible, it needs to be planned and operated smartly, especially if there are special requirements, or uses CNC-machines for processes like plasma-cutting or bending. In fact, the best and most powerful machine will not live up to its full potential, if it takes too long to bring new material, remove finished material, and calculate the required data for its operation. Upon closer examination transport and idle times are usually the biggest cost factors in pipe-shop operation, and they can often be traced either to a bad arrangement of machines / systems, or to bad process planning and organization. Mistakes here can have repercussions that may only be felt at later stages in the fabrication cycle, so attempts to make improvements at those stages do not address the actual problem. As an example, if a fitter takes 18 minutes to prepare a joint for welding, but it takes 20 minutes to deliver the pipe and fitting to him, then the problem is not on the fitter’s side, and improving his performance to 15 minutes per joint will only increase his waiting time, not his productivity. But since the fitters and welders are usually the final step in the prefabrication chain, it is here that the effects of any other, earlier bottleneck becomes visible. And thus fitting and welding is where most pipe-shop owners or managers focus their attention when it comes to improvements, often overlooking other problems in their fabrication cycle that need addressing.

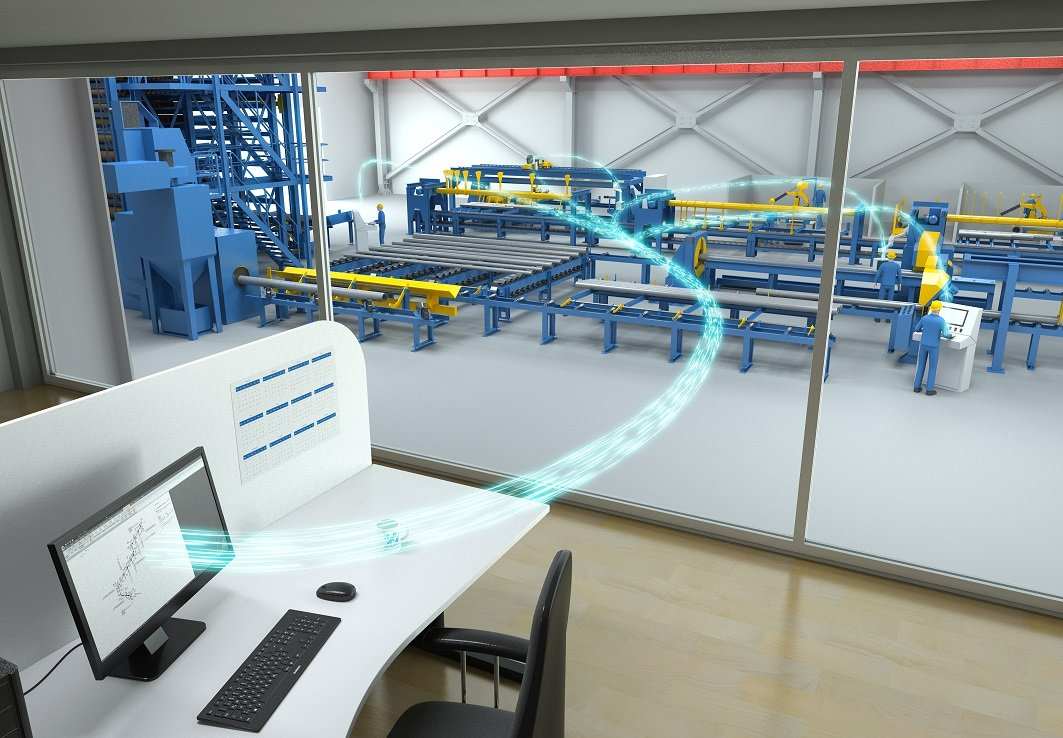

Image: Concept visualization of the transport system

3R solutions from Germany is a consultant and systems integrator who specializes in improving pipe-shop operations, through a mix of process automation, software integration, and optimized flow of material. Founded in the early 1980s the company can draw on many years of experience, as well as an extensive network of partner companies, who are leaders in their respective field. In addition to designing the pipe-shop, 3R solutions can also manage the entire project, selecting and procuring the machines, arranging transport and installation, and coordinating the different machine manufacturers on behalf of the client. By looking at all aspects of the fabrication cycle, 3R solutions can identify the bottlenecks and challenges, and create a concept for a streamlined and optimized workflow inside the shop.

Image: Actual installation of transport system

Since each client has different requirements and specifications, the first step in any project has to be an in-depth analysis and evaluation, in order to determine the optimal machines and arrangements. Depending on the pipe materials and dimensions, as well as standards and regulations, certain processes may not be suitable or even permitted, or certain machines may be more efficient than others. An expert like 3R solutions can help here, because they can determine whether a machine is viable or not, or if there is a better alternative more suitable for the individual client’s needs.

Another important factor is the level of automation in general. Unlike the automotive industry, where the same spool geometry is fabricated thousands, or even tens of thousands of times, the oil and gas industry generally requires a wide variety of geometries, which are then fabricated in small batches, or even individual units. Because of this a lot of pipeshop owners in this industry shy away from automation, thinking that their specific requirements mean that it is not possible to automate fabrication. However, while the spool geometries are much more diverse than in the automotive industry, the core processes remain comparable: handling, cutting, edge preparation, fit-up and welding. So even if automating the entire fabrication cycle may not be possible or economically viable, it is still possible to streamline and partially automate certain aspects of fabrication. And by optimizing the general flow of material and information inside the shop, the individual machines’ capacities can be utilized to a greater extent.

The machines for the workshop itself are generally selected based on performance and reliability, and are modified from their standard versions, in order to be included in an automated line. This modification can include certain interfaces to the machine control (in order to transfer certain parameters or data), or minor adjustments to the machine itself (for physical integration into the whole system, including emergency stop and safety processes). Machines are fabricated by leading manufacturers, many of whom have cooperated with 3R solutions for many years, on multiple projects. This long-term cooperation with customers and partners is a mainstay of 3R’s corporate philosophy. The idea is to involve the client in the planning process, in order to ensure that their requests and wishes are listened to, and implemented as much as possible. This includes not only the owners and managers, but also the operators and maintenance personnel, who will later have to work / service the equipment. They not only may offer valuable suggestions or input, but involving them in the planning process will help lower potential initial resentment against the idea of automation, and spark enthusiasm about the project as a whole.

The heart of 3R solutions’ system, however, is the planning and monitoring software, which has been continuously developed, expanded and improved in the past 40 years. It is not only applied in the workshop itself, where it provides work orders and tracks the fabrication status of each piece of pipe, but also in work preparation and process planning. The software is used to import the 3D model from 3rd party CAD platforms, and turns it into isometric drawings, which are then automatically split into spools for fabrication based on customizable parameters. For each spool the software can generate documentation such as part lists, cutting lists, welding information or work sheets, as well as CNC data for various processing machines such as plasma-cutting or pipe-bending machines.

By interfacing with material management and scheduling systems, it is possible to generate optimized work packages, with all relevant data already prepared in digital format, for paperless fabrication. Cutting lists are nested for reduction of scrap, and workloads are balanced between work stations / machines, in order to best utilize individual capacities. All processes are not only tracked, but documented, allowing for the creation of extensive reports for quality control, internal record keeping, and reporting to the end customer / buyer of the spools.

It is this combination of software and machines, proper planning and tracking, that helped 3R’s customers achieve significant improvements in their productivity, and build pipe-shops that became showcases for automation and process innovation.

If you would like to know more about how 3R solutions GmbH can help your company and its operations, please contact them at:

3R solutions GmbH

Tel: +49 2381 / 9724 – 710

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Web: www.3-r.de