The VTTI/ETT storage tanks in Rotterdam (The Netherlands) are in always in use. “This is an extra reason for us to ensure that the inspection of our tanks takes as little time as possible”, explains Ralph van Dijk of the company. The use of drones by Terra Inspectioneering offers a solution. Thanks to this technology the inspection duration has been shortened from two weeks to two days. The story of a customer from the very beginning.

The Euro Tank Terminal (ETT, part of the VTTI group) located in Europoort, Rotterdam has 36 storage tanks for the storage of fuel oil, jet fuel, methanol and gasoil. Next year, ETT will start using six new storage tanks on the site for the storage of fuel oil. “Apparently the market for fuel oil is still good,” explains maintenance engineer Ralph van Dijk of the tank storage company for the expansion.

FIRST MEETING

He says he is approached almost daily by parties who claim to have invented something very beautiful. “Nine times out of ten it turns out to be an empty shell,” he says. Terra Inspectioneering – formerly called RoNik Inspectioneering – was one of many companies that contacted ETT 5 years ago. “The company was still in its infancy”, says founder and commercial director Marien van den Hoek of Terra Inspectioneering. “We had just decided to focus on the inspection of confined spaces with drones. We had completed a pilot with Oiltanking in Terneuzen and because I knew the maintenance manager of ETT, we also knocked on this door.” Van den Hoek offered ETT to carry out the visual inspection of storage tanks using drones. An offer that Van Dijk heard with interest, but which he did not yet accept at the time. Van Dijk: “I said: ‘We only really benefit if the steel thickness can be measured.’ Otherwise I would still have to send people up into the tank.”

ADDED VALUE

A year and a half later, Van den Hoek reported again, this time with a drone that can perform both visual inspection and UT thickness measurements. This time, Van Dijk agreed: “As soon as we tried it out for the first time, I could already see that this way of inspecting offered added value. The problem with fuel oil storage tanks is that it is a heated product. The tank has PUF insulation, which you prefer not to remove. However, the heated fuel oil creates internal condensation, which increases the risk of corrosion. We’ve been running into this problem for several years now. We have had people measure the roof construction and walls using rope access, but that takes two weeks. You can also use crawlers, but for that the walls have to be cleaned thoroughly and you have to make holes in the roof because otherwise the equipment might fall and it must therefore be secured. That while the inspection by Terra Inspectioneering is completed within two days. That is why I welcomed them with open arms.”

VIDEO, FILM AND 3D MODELS

The fact that ETT’s storage tanks are full as standard is an important factor, according to Van Dijk. “At other storage terminals, there is often an empty tank, which makes it easier to take another tank out of operation. Then you move the contents from one storage tank to another. But we don’t have that luxury. If a tank has to be taken out of service for inspection, we always get in the way of the customer. They know that too, but apparently they find this a pleasant terminal, because we are always full. That is why it is very important for us to take storage tanks out of service for as short a time as possible. We use a pit-stop strategy for such situations, in which we prepare for worst-case scenarios. For example, we make agreements with contractors that they prepare their tools in advance. This is how we prepare for what we can reasonably expect. So you understand that it doesn’t make us very happy if we have to take a storage tank out of operation for two weeks for rope access. The time saved by using Terra Inspectioneering is therefore a major advantage. In addition, I can verify the data from the drones. The drones film and take pictures. The software can also create 3d models. Unlike the photos that rope access employees often take, the photo and video images from the drones are fantastic in quality.”

WALL, ROOF SHEETS ÁND CONSTRUCTION TRUSSES

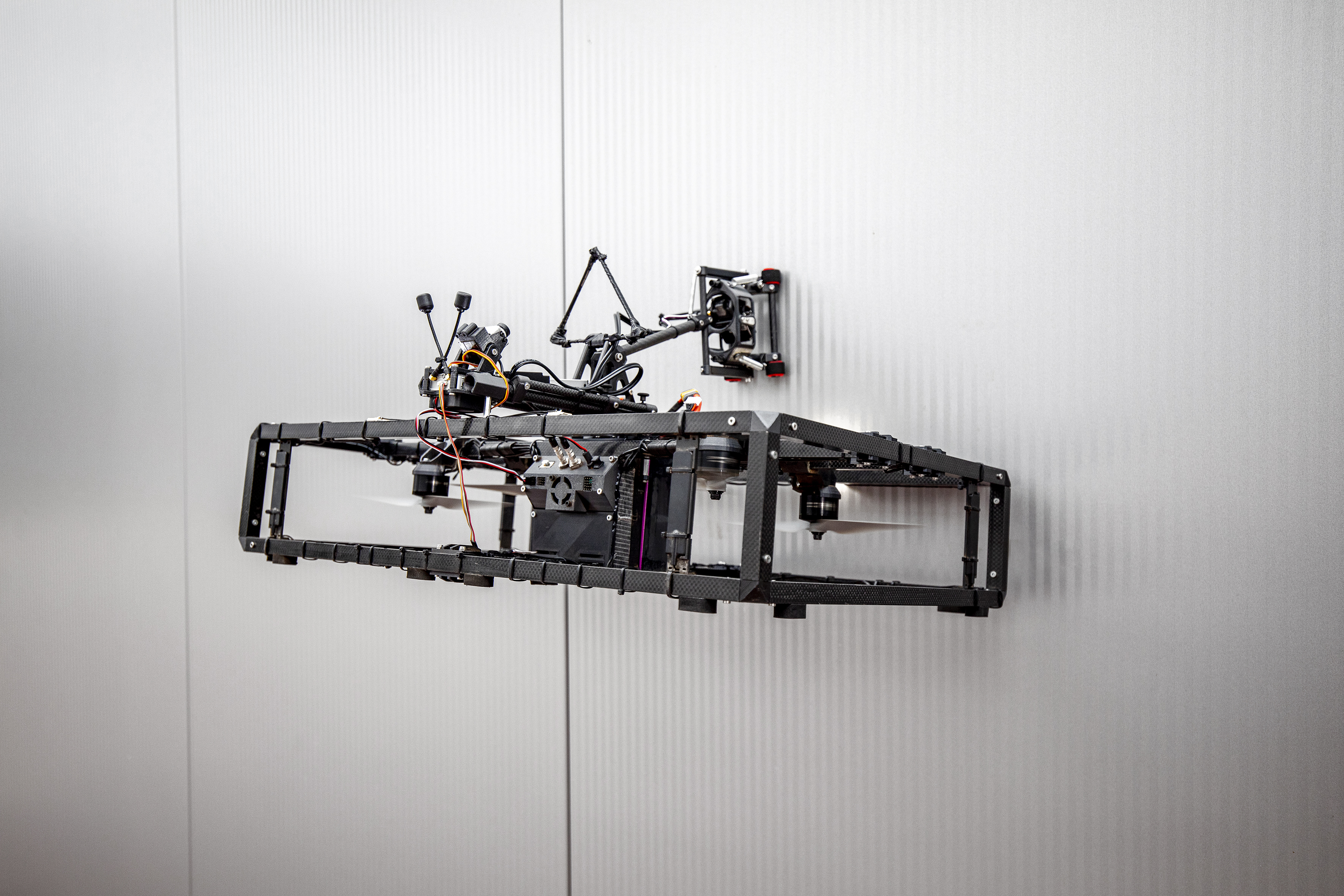

During one of the first test flights of a drone in a storage tank, Van Dijk had an eye-opener. “The drone was measuring in the tank, but got damaged. I thought this was a big deal, but the people at Terra said they could come back the next day. That evening, new parts of the drone would be 3D-printed.” This turned out to be possible because Terra designs the drones itself and also makes them with 3D printers. Initially, Terra’s drones only inspected the tank walls. Partly at the request of Van Dijk, Terra also started inspecting roof structures. So these are complex IPE or UNP rafters that have to be measured completely. “At first they only did the bottom flange, but Terra can now measure the entire profile. All standard sizes are measured, so that we have a good idea of the corrosion formation. Did this give me new insights? Not directly, but this is the realization of what I have always wanted. There can be problem areas in roof constructions, but they are difficult to reach. I now have a better view of the risks”, says Van Dijk.

POSSIBLE SOLUTION FOR CORROSION UNDER INSULATION

Terra Inspectioneering is one of a select group of suppliers with whom Ralph van Dijk of ETT likes to exchange ideas about ‘issues’. “They work with the content and come up with solutions. That is why I like to invest my time and energy here.” One of the topics that Ralph van Dijk and Marien van den Hoek of Terra Inspectioneering are studying is corrosion under insulation. “Certainly with our PUFsprayed storage tanks, this is a difficult problem to detect. It is a local problem that you usually do not pick up with internal measurements, but can have major consequences. In the worst case, you have a leak in a tank wall.” It is possible to visually inspect a tank wall with the aid of an aerial platform for defects that indicate corrosion. Insulation must then be removed in these places to check whether there are actually problems underneath. This is expensive and there is also a chance that places will be overlooked during visual inspection.

The use of the latest thermal imaging cameras on drones may offer a solution in combination with the latest AI (artificial intelligence) technology. ETT is discussing this with Terra Inspectioneering. “Thermal image makes temperature differences visible. Thermography allows you to detect wet insulation. However, temperature differences can also be caused by irregularities in the PUF insulation. In the past we have tested with thermography, but that turned out to be a problem and the results were therefore not reliable. We have developed new ideas with Terra Inspectioneering. How soon are we going to start testing? As far as I’m concerned, as soon as possible!” In addition, Terra Inspectioneering will carry out another pilot at ETT: visually inspecting pipe racks at height using drones. van Dijk: “We are going to see how it works, what it yields and what the reports look like. UT measurements are also a concrete option. If the test is successful, I would like to request the NL-CBI supervisor whether Terra Inspectioneering can carry out the inspection in this way on our pipelines that are subject to inspection. I expect this will not be a problem.”

Terra Inspectioneering B.V.

Voltaweg 11a

4382NG Vlissingen

The Netherlands

https://www.terra-inspectioneering.com

Phone: +31-85-3010095

Sales: +31-6-44557462

This email address is being protected from spambots. You need JavaScript enabled to view it.