OGI sits down with Hetraco B.V. to learn more about the work they do for the petrochemical, offshore, maritime, and building industries. Hetraco B.V. is a manufacturer of special fasteners with rolled thread. Particularly in the petrochemical industry, things can change very quickly and Hetraco helps us understand why it is so important to be able to act and react quickly, which helps their clients avoid costly downtime. Many companies don’t realize that when you buy high quality and reliable assets, you must use high quality and reliable fasteners as well.

OGI: Could you start by explaining Hetraco B.V.’s credentials and experience in terms of your products and services for the oil and gas sector? Could you tell our readers the breadth of your experience, how long the company has been active, and its reach?

Hetraco: Hetraco B.V. was founded in 1972 by Herman Hendriksen. The name Hetraco B.V. is an abbreviation of Hendriksen Trading Company. Hendriksen started selling turned, die-cast and bended products to industry and machine manufacturing companies from his home.

In 1982, Kees Eindhoven took over Hetraco B.V. and the company shifted its activities more towards the chemical industry and offshore, sectors which require fast delivery of special bolts, nuts and studs. To meet this need, Mark Eindhoven started his own production company, under the name Dutch Bolting Company B.V. (DBC).

In 2004, Hetraco B.V. was also acquired by Mark Eindhoven. This resulted in the ideal combination of an organization both purchasing and selling all types of fasteners materials available in the market, with the addition of the in-house production of ‘specials’.

2021

Hetraco has experienced enormous growth and presented it’s new strategic plan 2021-2025 together with a change of the board.

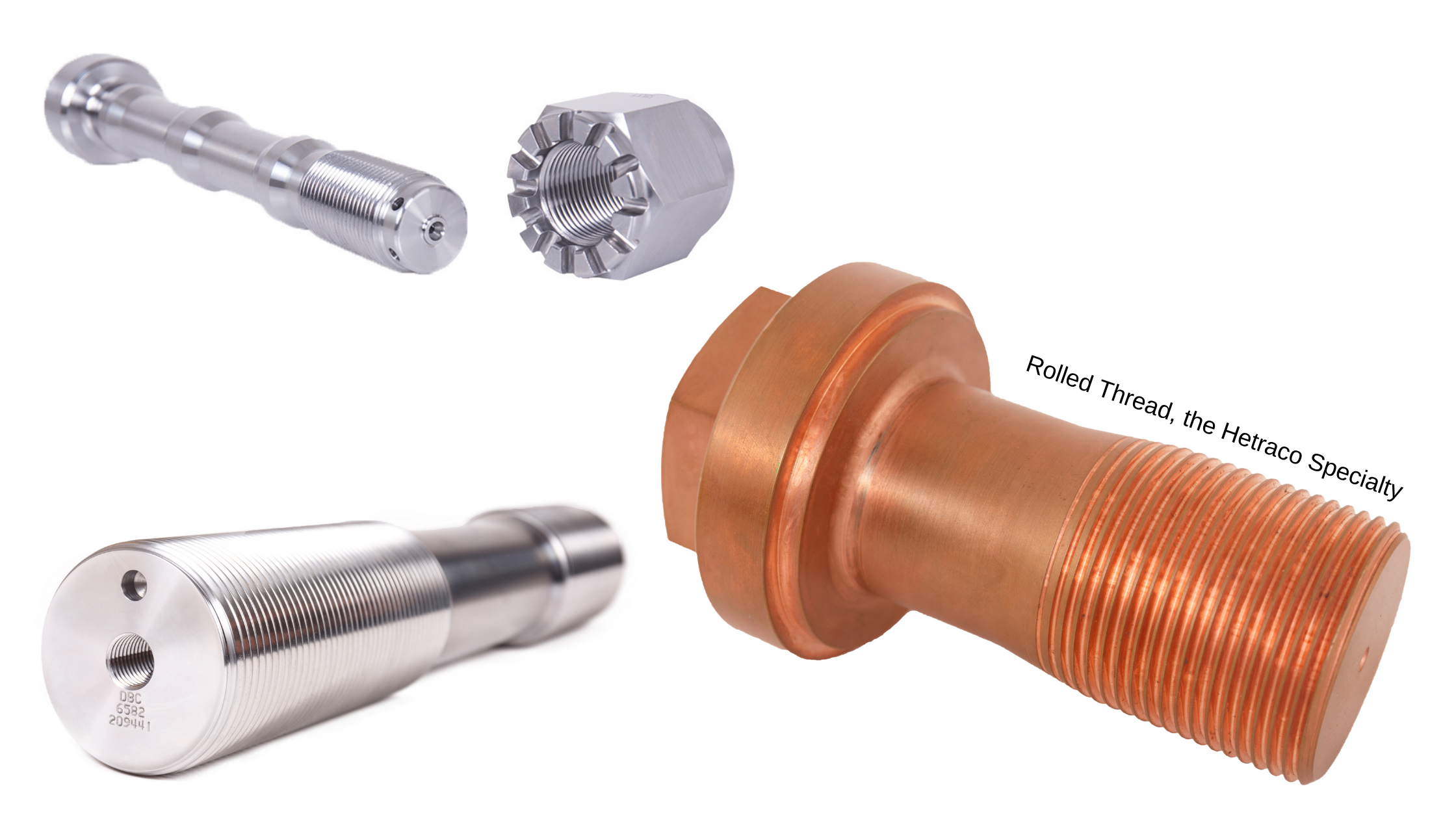

Nowadays we’re manufacturer of special fasteners with rolled thread. We deliver these products globally to a couple (focus) market segments like petrochemical, offshore, maritime and heavy industry building.

We always attempt to offer products to our customers with their requested delivery times. We have a high service grade, customer focus and deliver products with high quality are important for us. Also our flexible delivery times are one of the reasons why customers keep coming back.

In the future, Hetraco wants to continue growing, creating a stronger and even more solid organization.

OGI: Could you talk about the work you do with fasteners manufacturing?

Hetraco: We produce all kind of fasteners like bolts, nuts, studs and products according to drawings. Our specialism is “thread rolling” in all kinds of types, like Metric, UNC, UNF, 8-UN, BSW, etc. The dimensions we’re able to produce are from M5 – till M200.

Our production starts with searching the correct raw material according to the requested specifications. We have a large stock by ourselves with EU-materials, from standard steel, high temperature, stainless, Duplex and the Nickel Alloys.

The next phase is the production on our CNC-machines with turning & milling and final phase is thread rolling.

Recently we have invested in a Doosan Puma 700XLY which is capable of bars up to 5 meters between the centers. This machine is supported by 6 hydraulic steady rest for stable running.

OGI: Could you talk about the work you do in the offshore sector?

Hetraco: Currently we have been seeing a lot of changes within the offshore industry, nowadays the focus becomes more and more to the wind industry. At this moment we are building reliable and long-term partnerships with companies who are investing in this industry. You can think about Crane building, Gang-way production and all service-related companies.

We’re also very proud of a being a partner from Allseas and that we could deliver several projects for the Pioneering Spirit. This is a very positive reference for us to promote our business.

OGI: Could you talk about the work you do in the petrochemical sector?

Hetraco: Our experience in the petrochemical industry is already more than 30 years. This started with a couple refineries in The Netherlands where we delivered our special fasteners. Because we’ve expanded the capabilities of our own production facilities, we currently deliver our products on refineries through all Europe.

In this sector it is very important that you are able to act & react very fast. During a TA (turnaround) there will be around 2000-3000 people working on a plant. It is very important to get the downtime as short as possible.

Because of these extreme challenges we have created extra production capacities for our partners during these turnarounds. In preparation of the turnaround we have meetings what they expect from us. On this basis we can retain production time and people available even on the weekends if necessary.

OGI: Why is it so important to have the right partner in relation to fasteners?

Hetraco: I think that it is always (and for every part) important to have the right partner. Regarding the fasteners, these will usually be used at the end-phase, during the assembly or during the change when the turnaround already is started. These fasteners are often forgotten or ordered too late. Purchase departments sometimes thinks too easy about this and talk about special fasteners if you can pick them from stock.

When you expect a high quality and reliable product you also need to buy high quality fasteners. Build a good relationship with a manufacturer and give them also in an early stage the information about your expectations.

If you can manage this together the manufacturer has also the time to buy the correct raw material with the correct specifications. He will be able to manufacture fasteners on the requested delivery dates and is also able to produce the urgent unexpected deliveries during the turnaround.

OGI: What are the various products that you offer the oil and gas industries?

Hetraco: We are able to manufacture thread related special fasteners like bolts, nuts, studbolts and products according to drawings. The dimensions we are able to produce are from M5 till M200 and other types of thread like UNC, 8-UN, UNF, BSW, BSF, BSP, G, Metric Fine & customer specific.

Rolled Thread > that is our specialty!

In our production facility we have 6 thread roll machines; this is including our latest investment of the PR-100 which is a 100- Tons machine. Our staff has more than 20- year experience and we have a very good mix of personal for sharing knowledge and continue the future business. We are unique in the Benelux with this machine park and the capabilities we are able to offer.

OGI: Finally, could you enlighten our readers of a case study where you helped a client with your solutions?

Hetraco: We are not an engineering company who is able to develop new solutions or make calculations for projects. We are able to deliver to customer specifications and produce the products with the correct raw material, 98% from EU material.

If the customer has additional request like a surface treatment, Magnetic Particle Inspection, third party inspection or something else we are able to arrange this.

We would like to unburden the customer and along to simplify the process so that costs can be saved. You can think about a yearly based contract with raw material directly from mill manufacturer till simplify packaging or arrange weekly transport by ourselves.

We have several examples which are customer specific based, and we can tell you that we have saved thousands of euros together. It starts with a good inventory based on the wishes of the customer.

We look forward to get in contact with you!

OGI: Thank you for your time.

Hetraco B.V.

Tel: +31 55 303 21 80

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Web: www.hetraco.com